Flyability's Elios Cuts Downtime by 80% in Drilling Rig Ballast Tank Inspection

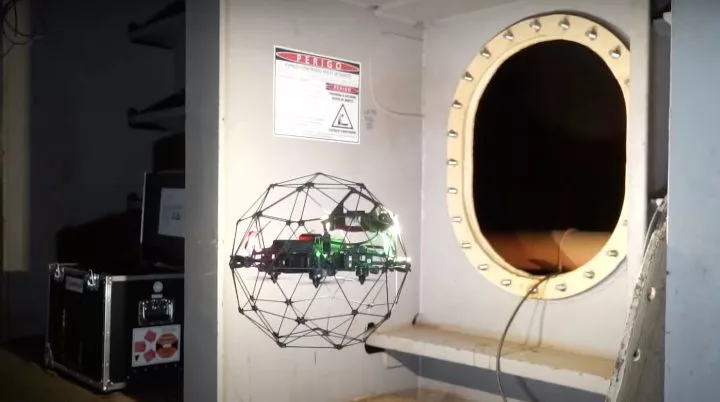

DR1 Group achieved an impressive 80% reduction in downtime during a ballast tank inspection on a drilling rig by using Flyability’s Elios 2. Discover how this innovative drone made a big difference. In the oil and gas industry, offshore drilling rigs are essential for extracting resources from beneath the ocean floor. These massive structures are designed to either sit on the seabed or float in deep water, depending on their location. For floating rigs, stability is maintained through a system of columns and underwater pontoons that house ballast tanks. These tanks play a critical role in controlling the rig’s buoyancy and balance. Regular inspections of these areas are vital to ensure operational safety and efficiency. The drilling rig DR1 Group inspected Given the complexity and risks involved, traditional methods like rope access have long been used to inspect these hard-to-reach areas. However, such methods can be dangerous, time-consuming, and costly. A shipyard in Angra dos Reis, Brazil, was looking for a safer and more efficient way to inspect its drilling rigs. Previously, they relied on rope access, which posed significant safety risks and extended the time the rig was out of service. To address these challenges, the shipyard reached out to DR1 Group to conduct a trial inspection using drones. Their goal was to evaluate whether aerial technology could offer a better solution. DR1 Group collaborated closely with the shipyard to plan two test missions: one for external inspections of the rig and another for internal inspections of the ballast tanks. For the internal inspection, they used Flyability’s Elios 2, a rugged drone designed specifically for confined spaces. This allowed them to gather high-quality visual data without the need for human entry into hazardous environments. Over the course of two months, DR1 worked with the shipyard to ensure all legal and safety requirements were met. This preparation helped make the test missions both effective and compliant. The internal inspection test was a huge success. In just 30 minutes of flight time, the Elios 2 covered 40% of one of the ballast tanks. With additional battery swaps and real-time footage reviews, the full inspection took about two hours. Based on these results, the shipyard estimated that using the Elios 2 could reduce the total time needed for internal inspections from 60 days to just 20 days. That’s a dramatic improvement in efficiency and cost savings. This video shows some of the footage captured during the ballast tank inspection: After reviewing the data, the shipyard was extremely satisfied with the results. They saw a clear improvement in safety, efficiency, and cost-effectiveness compared to traditional methods. Here are some of the images captured inside the ballast tank: The tests were conducted in early 2020, but operations were temporarily halted due to the COVID-19 pandemic. However, the shipyard has since resumed work and plans to bring DR1 Group back for future inspections. With several other rigs in their fleet, the shipyard is now considering hiring DR1 Group to use the Elios 2 for internal inspections across all their platforms. DR1 has also continued using the Elios 2 for various confined space inspections in the oil and gas sector, including ballast tanks and cargo tanks on FPSOs. As the industry continues to evolve, the use of drones like the Elios 2 is proving to be a game-changer—offering safer, faster, and more cost-effective solutions for critical maintenance tasks. Tablet Capsule Counting Machine

The capsule counting machine adopts electromagnet vibration effect, stable and reliable; Scientific design, simple, easy to use, small size, light weight, suitable for pharmaceutical, hospital, food and other industries, for capsules, tablets, particles and other drugs or food counting. This machine is small in size, light in weight, accurate in counting and easy to operate. The contact surface of counting items are made of stainless steel, which is an ideal special equipment for counting bottled, bagged and canned products in various industries.

1. The number of counting particles can be set anywhere from 0 to 9999;

Tablet Capsule Counting Machine,Tablet Counting Machine,Capsule Counting Machine,Pill Counter,Desktop Quantitative Machine JIANGYIN CITY XUAN TENG MACHINERY EQUIPMENT CO.,LTD , https://www.xuantengmixer.comFlyability's Elios Helps DR1 Group Cut Downtime by 80% in Ballast Tank Inspections

Key Benefits at a Glance

Savings

The use of the Elios 2 led to a 60% cost reduction for the ballast tank inspection.

Reduced Downtime

With the Elios 2, the inspection time was cut from five days to just one, achieving an 80% reduction in downtime.

Safety

No need for confined space entry or rope work—inspections were conducted safely and efficiently with the Elios 2.

Introduction

Customer Needs

The Solution

Results

Conclusion

2. The stainless steel of the machine complies with GMP standards;

3. Simple operation, no special training required;

4. Precision particle counting, equipped with special electric eye protection device;

5. Rotary counting design, fast and smooth operation;

6. The rotating particle counting speed can be stepless adjusted according to the manual bottling speed;

7. Vacuum cleaner is installed inside the machine to avoid the influence of dust on the machine;

8. Vibration feeding design can stepless adjust the vibration frequency of the hopper.