Inspection Tools: A Guide to the Tools Inspectors Use in Their Daily Work

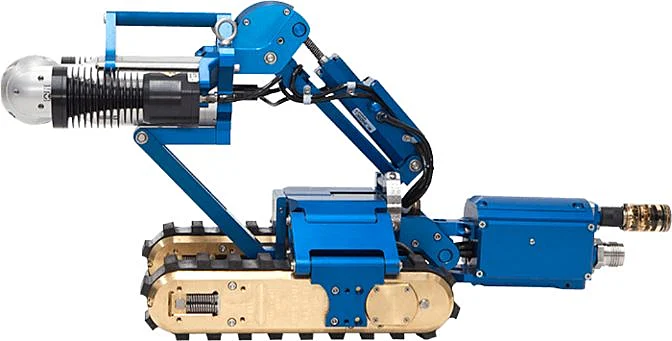

Inspection tools are essential for gathering critical information that ensures the safety, functionality, and longevity of various assets. Whether it's a large industrial structure or a small HVAC unit, these tools enable inspectors to perform their duties effectively and efficiently. The type of data collected by inspectors depends on the specific requirements of the inspection. This could include visual, thermal, or thickness measurements. The choice of inspection tools is directly influenced by the kind of data needed, which in turn determines the methods and technologies used during the process. Once data is collected, inspectors analyze it to assess the condition of the asset and determine if any maintenance or repairs are necessary. This step is crucial for preventing failures and ensuring compliance with industry standards. In this article, inspection tools refer to the actual instruments used to gather data, such as sensors, cameras, or drones. These tools are designed specifically for collecting information about the condition of an asset. For example, a thickness measuring sensor might be used to evaluate the integrity of a wall inside a coke drum, while a drone equipped with a camera can access hard-to-reach areas to capture visual data remotely. Inspection equipment, on the other hand, includes anything that supports the inspector’s work, such as tool belts, scaffolding, or ropes. This category covers all the gear that helps inspectors reach and interact with the asset being inspected. [Related read: Confined Space Equipment: A Guide] Whether inspecting a massive boiler or a home HVAC system, the process remains consistent: While the core concept is straightforward, the variety of inspection tools used can be vast, depending on the nature of the job and the type of data required. These tools can often be grouped based on the type of data they collect. However, in the case of robotics, the way data is collected (e.g., aerial or ground-based) may take precedence over the type of data itself. Now, let’s explore the different types of inspection tools used in the field.  Visual data is one of the most commonly collected types of information during inspections. Cameras are the primary tool for capturing this data, but not every camera is suitable for every inspection. The key factor when selecting a camera is whether it can meet the specific data requirements of the inspection. If the camera can deliver high-quality images that support the inspection’s goals, it’s the right tool for the job. Here are some common visual data collection tools: While visual data is the most common, many inspections require additional types of data, such as thermal, ultrasonic, or radiographic information. Each of these requires specific sensors or non-destructive testing (NDT) methods. A recent inspection conducted by Premium Inspection & Testing in Louisiana demonstrates how a combination of tools and NDT methods can be used effectively. To inspect a coke drum without scaffolding, the team used drones and rope access to collect all necessary data. The steps taken included: 1. Visual data collected by drone Using the Flyability Elios 2 drone, inspectors gathered visual data inside the coker to check its cleanliness and identify areas requiring closer attention. 2. Corrosion and pitting data collected via rope access With rope access, the team performed tests like 3D scanning, phased array testing, and liquid penetrant testing to assess the condition of the coke drum. This approach not only saved time and money but also significantly reduced costs for the client. Some examples of data that may require specialized tools include: For more on NDT methods, check out our comprehensive guide. Robotic solutions have become increasingly popular in the inspection industry, offering safer and more efficient alternatives to traditional methods. There are three main categories of robotic tools used by inspectors: Drones are now widely used for remote data collection, especially in environments where human access is limited or dangerous. They are particularly useful for visual inspections, though some models can also collect thermal or other types of data. There are several benefits to using drones for inspections: Indoor drones are designed for confined spaces and are built to withstand collisions, making them ideal for inspecting boilers, tanks, and pressure vessels. An example is the Flyability Elios 3, which operates safely in tight environments. Outdoor drones, on the other hand, are used for larger, open-area inspections and do not have the same level of collision resistance. The DJI Matrice 300 is a popular model for outdoor use. Ground-based robots offer similar advantages to drones, enabling safe and efficient data collection in challenging environments. Some examples include: The Inuktun MaggHD is a magnetic crawler used for remote visual inspection in hazardous areas. The Deep Trekker DT320 is a pipe crawler used for inspecting sewers and other difficult-to-access areas. The Inuktun Versatrax 150 is a long-range crawler used for inspecting tanks and wastewater infrastructure. Submersible robots are becoming increasingly important in underwater and liquid-filled environments. They allow inspectors to collect data in places that would otherwise be inaccessible or dangerous. MASKI+ The Maski+ ROV provides HydroQuebec with access to areas too deep or turbulent for divers. It features multiple cameras and sensors for comprehensive inspections. INTERO TANK EXPLORER The Intero Tank Explorer is a submersible robot designed for use in explosive environments, such as petrochemical storage tanks. It can detect thickness inconsistencies and provide real-time images while the tank is in operation. Future inspections will rely on even more advanced robotic tools, including those equipped with NDT sensors. For example, robot-mounted ultrasonic testing tools are already being used in various industries. Newer robots are also being developed to inspect hazardous or inaccessible locations, such as aging sewage systems. Some models can even fix identified issues using onboard tools like water-jet cutters or UV-curable patches. Measuring devices are a crucial part of the inspection process, allowing inspectors to collect precise dimensional data. These tools range from simple hand-held calipers to sophisticated digital gauges. Common measuring devices include: As inspections become more data-intensive, managing and analyzing the collected information has become a major challenge. This is where inspection software plays a vital role. Two key areas of innovation are improved data collection and enhanced data management. Modern software allows for streamlined workflows and better integration with remote inspection tools. Software like Flyability Inspector 3.0 offers 3D modeling capabilities, automatically generating models of the inspected asset and highlighting defects. This makes the inspection process more efficient and accurate. Advanced software solutions can handle large volumes of data, and the integration of AI and machine learning is helping inspectors process and interpret data more quickly. This leads to faster decisions and safer outcomes. Whether through new innovations or refined tools, every advancement in inspection software contributes to more efficient and effective inspections, ultimately improving safety and performance across industries. Steel Cylinder Caps & Valve Guards

All cylinders with a threaded necking are required to have cylinder caps in place when being stored full or empty. Compatible With Select cylinders, Product Type Cylinder cap. These caps have the durability to withstand cylinder falls and keep the valve protected Cylinder valve protection is paramount when moving or storing a cylinder.

Stamped Welded Cylinder Guards,Gas Cylinders Guards,Cylinders Guards,Lpg Cylinders Guards Hangzhou Qizheng Trading Co., Ltd. , https://www.gascylindercap.comInspection Tools: A Guide to the Tools Inspectors Use in Their Daily Work

Inspection tools help inspectors collect the data they need to ensure the proper maintenance of the assets they're inspecting—Read this guide for an overview of the different types of inspection tools they use.

Understanding Inspection Tools vs. Inspection Equipment

Cameras and Visual Data Collection Tools

A borescope being used to inspect a car engine

A borescope being used to inspect a car engine

Other NDT Sensors and Testing Methods

Ropes and Drones Case Study

Photo credit: Premium Inspection & Testing

Photo credit: Premium Inspection & TestingNDT Sensors and Testing Methods

Robots in Inspection

Drones / Aerial Solutions

Why Use RVI Tools?

Indoor vs. Outdoor Drones

DJI's Matrice 300, an outdoor drone commonly used in inspections

DJI's Matrice 300, an outdoor drone commonly used in inspectionsGround-Based Robotic Solutions

Inuktun MaggHD

Deep Trekker DT320

Inuktun Versatrax 150

Submersible Robots

Recent Advances in Robotics

Measuring Devices

Inspection Software

Improved Data Collection Software

Data Management Tools