Introduction to the Stepper Motor Linear Actuator Attachment

June 04 03:19:04, 2025

The demand for micro linear actuators has been growing steadily due to the need for increased productivity in tight spaces. To cater to this trend, Oriental Motor has developed a compact linear actuator that can easily attach to standard stepper motors.

According to Verified Market Reports, the global Micro Linear Actuators Market was valued at USD 1.50 billion in 2023 and is projected to reach USD 4.20 billion by the end of 2030, with a Compound Annual Growth Rate (CAGR) of 15.85% during the forecast period of 2023-2030. Claude 3.5 Sonnet predicts that the US micro linear actuators market could potentially see a CAGR of around 9-11% over the next decade, translating to a total growth of approximately 140-180% over the 10-year period.

This growth is expected to be driven by rising adoption in sectors such as medical and healthcare, industrial automation and robotics, consumer electronics, automotive (electric and autonomous vehicles), and aerospace/defense industries.

**What is the Stepper Motor Linear Actuator Attachment?**

The Stepper Motor Linear Actuator Attachment is a mounting adapter that includes a lead screw and a high-wear-resistance resin nut. It can be easily attached to off-the-shelf stepper motors, much like a gearhead, converting rotary stepper motion into precise linear motion, similar to an external type stepper motor linear actuator.

**Installation**

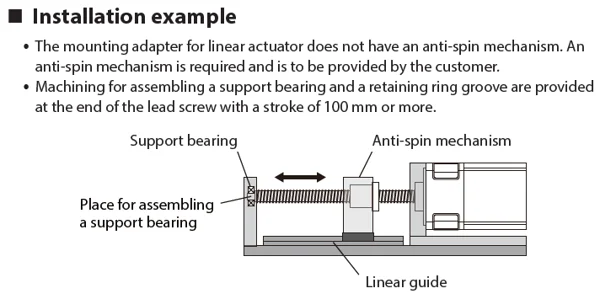

Since the Stepper Motor Linear Actuator Attachment lacks an anti-spin mechanism, it must be provided by the customer. Without this mechanism, the nut will simply spin in place without moving. Below is an example of a finished assembly featuring the Stepper Motor Linear Actuator Attachment, an anti-spin mechanism, support bearings, and a linear guide. Note that limit switches or sensors are not included and will need to be installed separately, such as on the linear guide.

**What Makes It Unique?**

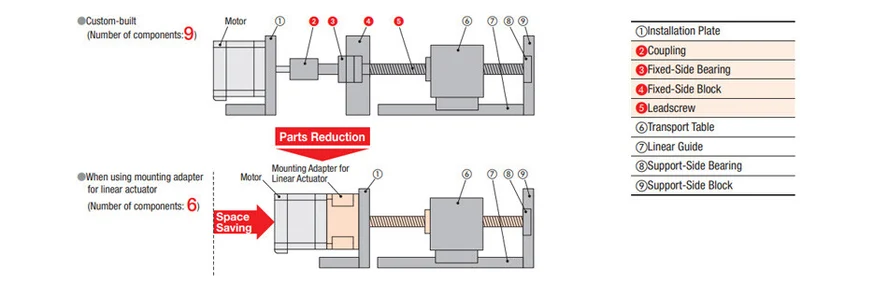

The Stepper Motor Linear Actuator Attachment can be installed directly onto a stepper motor output shaft without requiring a coupling mechanism. This reduces the number of necessary components, saving space and speeding up the design process compared to custom-built linear actuators. For instance, in the example shown, the number of components was reduced from 9 to 6 by eliminating the coupling, fixed-side bearing, fixed-side block, and a standalone leadscrew.

**Compatible Lineup**

Various types of PKP Series high-torque stepper motors and CVD Series bipolar microstepping drivers can be combined to create different types of stepper motor linear actuators. Below is a diagram showing the combinations possible with our extensive product lineup.

**Application Examples**

For point-to-point applications where space is limited, such as syringe pumps and test tube transfer, the Stepper Motor Linear Actuator Attachment offers a cost-effective solution. For example, three sets of stepper motors and linear actuator attachments provide precise linear motion for syringe pumps in a slim profile. Similarly, this attachment can be used to transfer test tubes linearly from one location to another, with an external guide recommended for enhanced precision.

**Have Questions?**

Our team is here and ready to address any queries you might have. Whether you’re looking to enhance motor performance, achieve better repetitive positioning accuracy, or integrate closed-loop absolute control, Oriental Motor’s comprehensive range of products can meet your needs.

---

Let us know how we can assist you further!