Introduction to the Stepper Motor Linear Actuator Attachment

June 04 03:16:00, 2025

The growing demand for micro linear actuators is primarily driven by the need to enhance productivity in tight spaces. To cater to this trend, Oriental Motor has introduced a compact linear actuator attachment that can be easily mounted onto standard stepper motors.

According to Verified Market Reports, the global Micro Linear Actuators Market was valued at $1.5 billion in 2023 and is projected to reach $4.2 billion by 2030, representing a Compound Annual Growth Rate (CAGR) of 15.85% during the forecast period of 2023-2030. Claude 3.5 Sonnet suggests that the US micro linear actuators market might experience a CAGR of around 9-11% over the next decade, resulting in an approximate 140-180% growth over the ten-year span.

This growth is expected to be fueled by increasing adoption across various sectors including medical and healthcare, industrial automation and robotics, consumer electronics, automotive (especially electric and autonomous vehicles), and aerospace/defense industries.

Let’s explore what this stepper motor linear actuator attachment entails:

**What is the Stepper Motor Linear Actuator Attachment?**

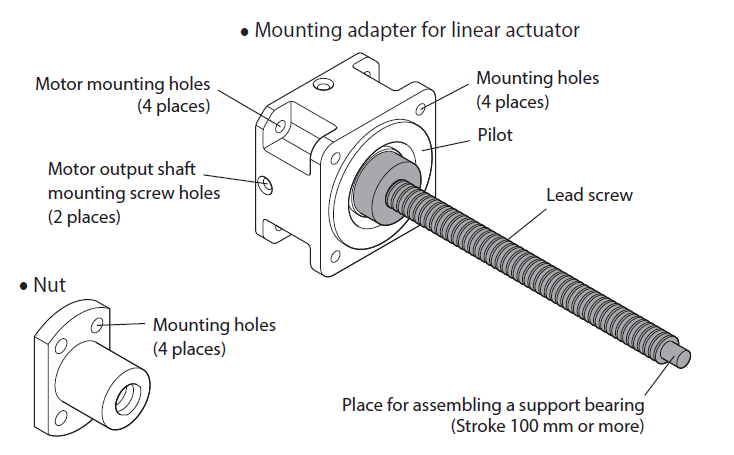

The Stepper Motor Linear Actuator Attachment is essentially a mounting adapter that includes a lead screw and a resin nut with high wear resistance. It can be effortlessly attached to standard stepper motors, much like a gearhead, and transforms rotational stepper motion into precise linear motion—functioning similarly to an external type stepper motor linear actuator.

Here's a visual representation:

**Installation**

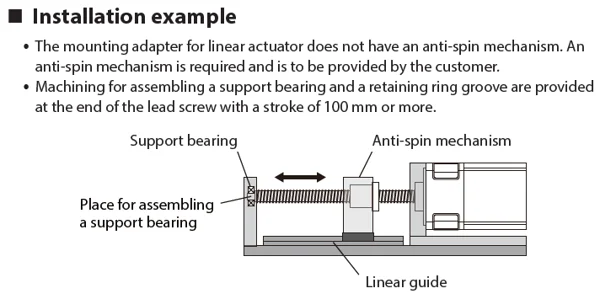

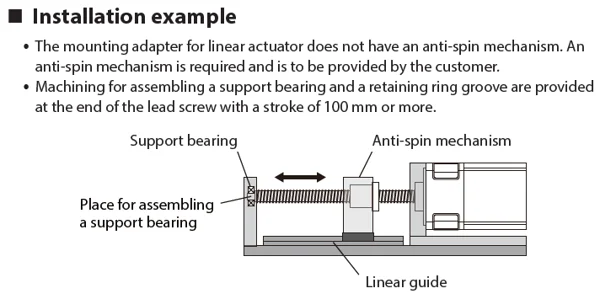

It’s important to note that the Stepper Motor Linear Actuator Attachment doesn’t come with an anti-spin mechanism, which needs to be provided by the user. Without it, the nut will simply spin in place without moving. Below is an example of a completed assembly featuring a Stepper Motor Linear Actuator Attachment, an anti-spin mechanism, support bearings, and a linear guide. Please keep in mind that limit switches or sensors are not included and should be installed separately, such as on the linear guide.

**What Makes it Unique?**

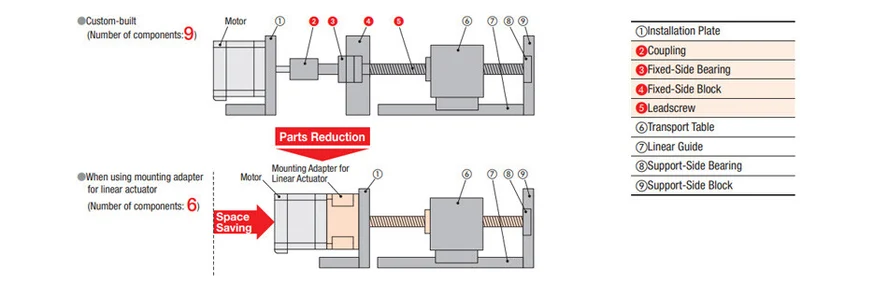

The standout feature of this attachment is its ability to be mounted directly onto the stepper motor output shaft without requiring a coupling mechanism. This reduces the number of necessary components, saving space and expediting the design process compared to custom-built linear actuators.

For instance, by using this attachment, we can reduce the number of components from 9 to 6 by eliminating the coupling, fixed-side bearing, fixed-side block, and a standalone leadscrew.

**Installation Example**

Take a look at this installation example for the linear actuator attachment:

**Compatible Lineup**

The Stepper Motor Linear Actuator Attachment pairs well with various types of PKP Series high-torque stepper motors and CVD Series bipolar microstepping drivers. This allows users to create different configurations of stepper motor linear actuators. Here’s a glimpse of the combinations available with our extensive product lineup:

**Application Examples**

For point-to-point applications where space is limited, such as in syringe pumps and test tube transfer systems, the Stepper Motor Linear Actuator Attachment offers a cost-effective solution.

Here's how it works in a syringe pump application:

And here's an example of test tube transfer:

Both applications demonstrate how these actuators provide precise linear motion in compact designs.

**Have Questions?**

If you have any queries, our team is ready to assist you and address any concerns you may have.

---

Feel free to reach out if you'd like further details or assistance!

TOPICN is a professional manufacturer for centrifugal casting products applied in the petrochemical industry, including reformer tube used in hydrogen generation plant and direct reduced iron (DRI) plant, Ethylene Cracking Tube and other centrifugal casting tube for petrochemical industry