Flexible Mounting Options for Compact Stepper Motor Drivers

June 04 04:07:15, 2025

In any stepper motor system, having a reliable driver is essential. The driver acts as the brain of the operation, interpreting signals from the controller and determining how the motor will function. It manages the flow of current through the various phases of the stepper motor and ensures that the motor operates smoothly and efficiently. As machines continue to shrink in size, finding enough space to install a driver has become a growing challenge.

A typical stepper motor setup includes a driver positioned alongside the motor, but in many modern applications, space constraints make this configuration impractical. To address this issue, Oriental Motor has developed a range of stepper motor drivers with flexible mounting options to accommodate different machine designs.

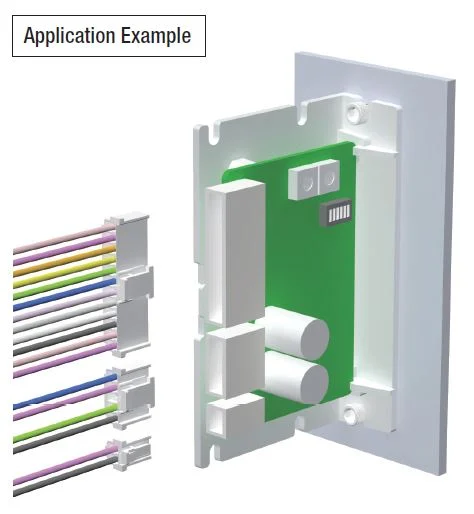

**Challenge 1: Installing a Driver Vertically with Horizontal Connections**

**Solution:** Utilize a Right-Angle Driver with a Mounting Plate

This type of driver features connectors that face outward, parallel to the circuit board. It comes equipped with mating connectors and can be paired with a driver cover and a DIN rail mounting bracket for added versatility.

*Image: Right Angle Driver with Mounting Plate*

Additionally, Oriental Motor offers several accessories to enhance the functionality and adaptability of these drivers:

- **Driver Cover**: Provides extra protection.

- **DIN Rail Mounting Bracket**: Facilitates easy installation.

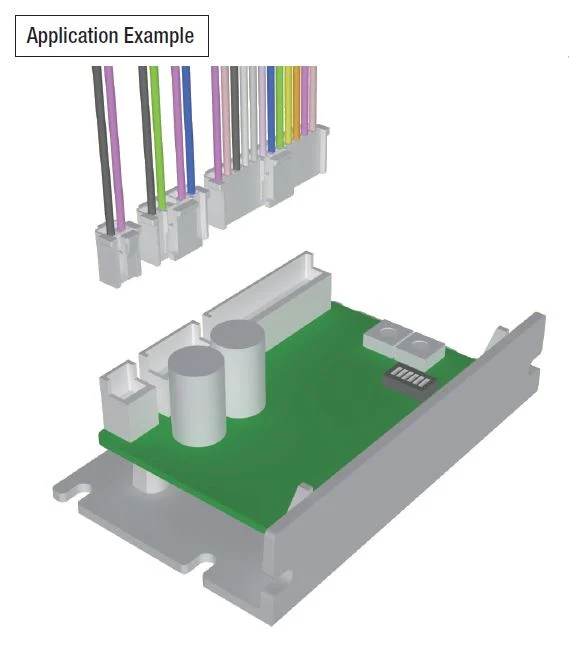

**Challenge 2: Installing a Driver Horizontally with Vertical Connections**

**Solution:** Use a Driver with a Mounting Plate

In this case, the connectors face upward, perpendicular to the circuit board, making it ideal for horizontal installations.

*Image: Driver with Mounting Plate*

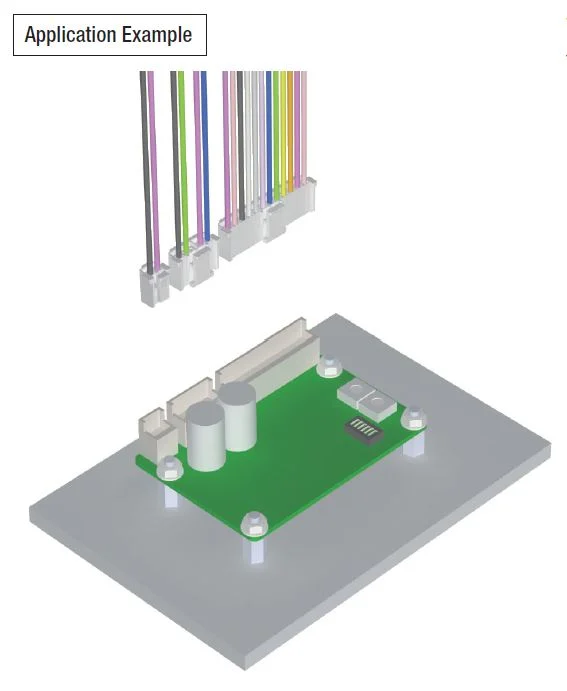

**Challenge 3: Direct Mounting on a Metal Plate**

**Solution:** Opt for a Driver Without a Mounting Plate

These drivers feature upward-facing connectors and are designed with high-efficiency FETs, eliminating the need for a heat sink. They also come with mating connectors.

*Image: Driver Without Mounting Plate*

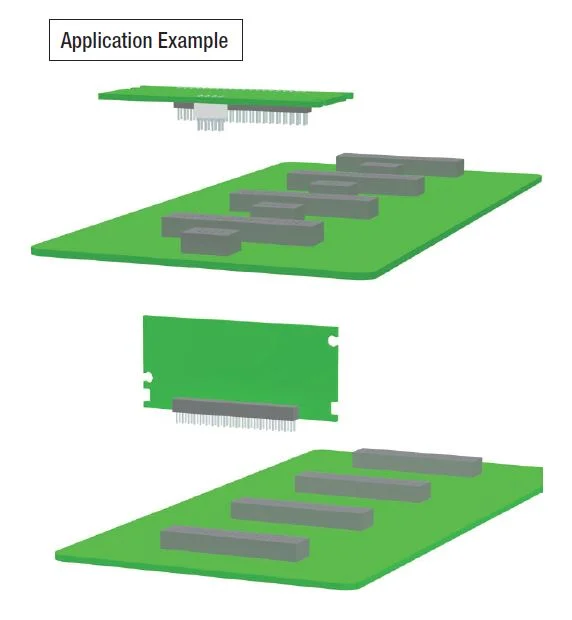

**Challenge 4: Direct Installation onto a PCB**

**Solution:** Choose S-Type Drivers

S-Type drivers are perfect for engineers who prefer custom designs. They can be installed directly onto a printed circuit board (PCB) via pin sockets or direct soldering. These drivers are available in both vertical and horizontal configurations and support I/O-only or SPI (Serial Peripheral Interface) bus communication.

*Image: S-Type Driver*

To learn more about how Oriental Motor’s CVD drivers can enhance stepper motor performance, consider exploring our offerings for both 2-phase and 5-phase stepper motors. While 2-phase motors are more common, 5-phase motors offer even smoother and quieter operation.

*Image: CVD Drivers for 2-Phase Stepper Motors*

*Image: CVD Drivers for 5-Phase Stepper Motors*

For a quick overview of the CVD driver's features, check out this short video:

- Smooth Drive full-time advanced microstepping

- High-efficiency FETs

- Digital current setting

- Vibration reduction at resonant frequencies

- Versatile mounting options

If you’re unsure which driver is best suited for your stepper motor, don’t hesitate to reach out. Our team is here to assist you in selecting the perfect solution.

*Image: Contact Us*

Oriental Motor remains committed to innovation and providing solutions that meet the evolving needs of our customers. Whether you’re designing compact machinery or upgrading existing systems, our flexible mounting options ensure that every component fits seamlessly into your design.

1.5-1.7 ton Mini Excavator, the overall use of engineering additive track, wear-resistant and stable;

This kind of small excavator has beautiful appearance, full power, three-cylinder engine and stable performance;

The front end can be equipped with a side swing function, flexible operation in a small space, large counterweight, and the excavator does not tilt its head when the excavator, and the digging force is increased.

Suitable for small projects in your own garden nursery.

Hydraulic Crawler Excavator,Bucket Mini Excavators,1 Ton Mini Excavator,1 Ton Excavator