Flexible Mounting Options for Compact Stepper Motor Drivers

June 04 04:06:31, 2025

Sure! Here’s the rewritten content in English:

---

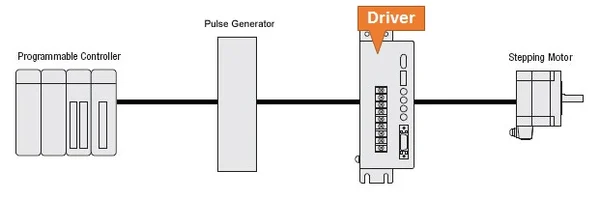

A stepper motor driver is an essential component for any stepper motor system. It interprets signals from the controller and manages the operation of the stepper motor by controlling the flow of current through its various phases. The driver not only regulates the motor current (torque) but also determines the step resolution. As machines become increasingly compact, finding space for installing drivers has become a challenge.

**Standard Stepper Motor System Configuration**

Oriental Motor understands this trend and has developed stepper motor drivers with versatile mounting options to suit a variety of machine designs.

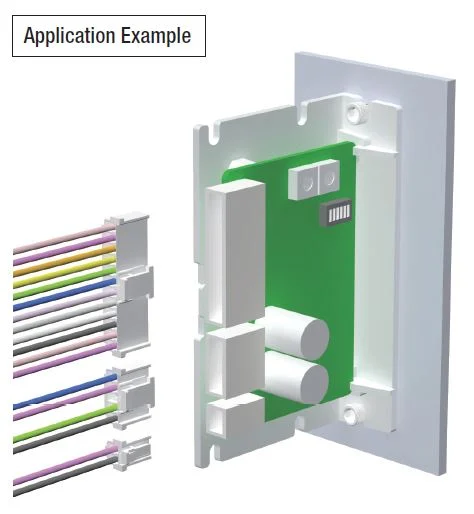

**Challenge 1: Installing a Driver Vertically with Horizontal Connections**

*Solution: Use a Right Angle Driver with Mounting Plate*

This type of driver has its connectors facing outward (parallel to the circuit board), making it easier to connect mating connectors. It can also be combined with a driver cover and DIN rail mounting brackets.

**Accessories:**

- **Driver Cover**

- **DIN Rail Mounting Bracket**

These accessories ensure secure installation and optimal performance.

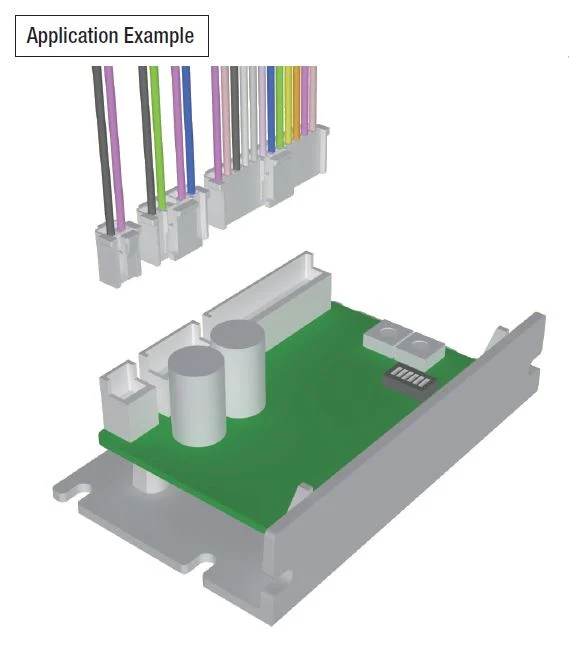

**Challenge 2: Installing a Driver Horizontally with Vertical Connections**

*Solution: Use a Driver with Mounting Plate*

This driver has its connectors facing upward (perpendicular to the circuit board), allowing for a more compact setup.

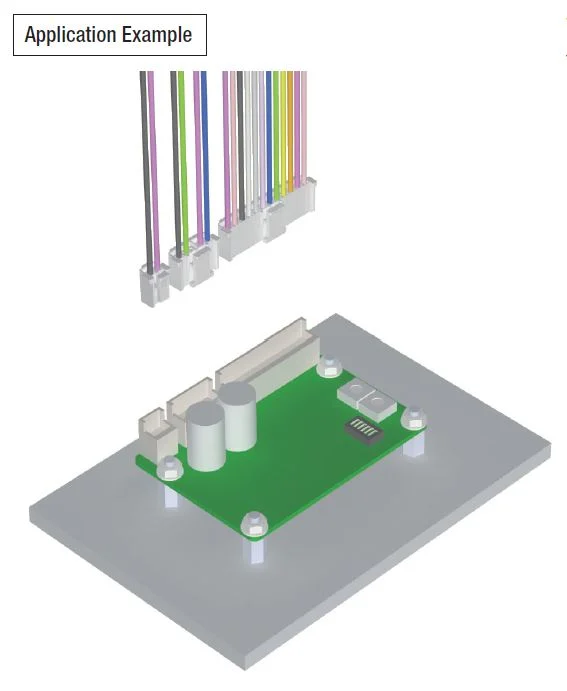

**Challenge 3: Attaching the Driver Directly to a Metal Plate**

*Solution: Use a Driver without Mounting Plate*

This type of driver has its connectors facing upward as well, eliminating the need for a mounting plate. Design innovations like high-efficiency FETs reduce the need for a heat sink.

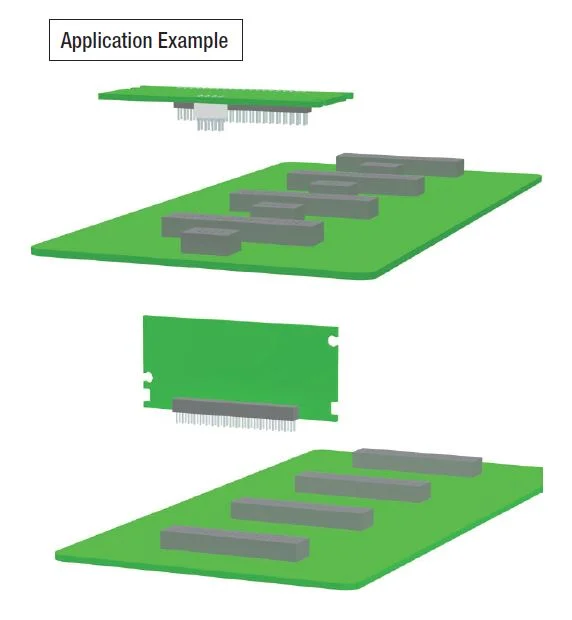

**Challenge 4: Direct Installation of the Driver onto a PCB**

*Solution: Use S-Type Drivers*

S-Type drivers are ideal for engineers who want to integrate them into custom designs. They can be mounted directly onto a printed circuit board (PCB) via pin sockets or direct soldering. Both vertical and horizontal S-type drivers are available with either I/O only or SPI (Serial Peripheral Interface) bus communication.

To learn more about how our CVD drivers can enhance stepper motor performance, check out the products below. We offer CVD drivers for both 2-phase and 5-phase stepper motors. While 2-phase motors are more common, 5-phase motors provide even smoother and quieter operation.

[CVD Drivers for 2-Phase Stepper Motors](http://bsg-i.nbxc.com/blog/73f0c3317774699c38aaa9c959dcf58c.png)

[CVD Drivers for 5-Phase Stepper Motors](http://bsg-i.nbxc.com/blog/69ba64bf2a63a542100f689a8c8d025a.png)

Here’s a quick video introducing the key features of the CVD driver:

- Smooth Drive full-time advanced microstepping

- High-efficiency FETs

- Digital current setting

- Vibration demonstration at resonant frequencies

- Versatile mounting types

If you need help choosing the right driver model for your stepper motor, feel free to reach out to us.

[Contact Us](http://bsg-i.nbxc.com/blog/33a4c2c5bd5f1c847566aefff19d14c6.png)

---

I hope this version meets your requirements! Let me know if you need further adjustments.

SD35U is a car with the highest configuration in the micro-digging industry. The original imported Yangma engine is durable, fuel-efficient and low noise.Disc - type design structure, design science, rigorous, all accessories at a glance.

This SD35u small excavator weighs about 3300kg

relatively small and flexible

YANMAR 3TNV88,Engine power 19.6KW

bucket capacity 0.09 m³

3.5 Ton Mini Tailless Excavator,3.5 Ton Micro Digger,3.5 Ton Tailless Small Digger,Hydraulic Tailless Crawler Excavator