Why Electric Actuators Are Better Than Pneumatic Actuators for Packaging Machinery

June 07 04:23:51, 2025

As the packaging industry continues to evolve, the demand for efficient and reliable machinery is on the rise. Historically, pneumatic actuators have been the preferred choice for many packaging and labeling machines due to their simplicity and cost-effectiveness. However, electric actuators are now gaining traction because of their numerous advantages. In this article, we’ll explore how electric actuators are reshaping the packaging machinery landscape.

---

**The Evolution of Actuators in Packaging**

One of the most significant differences between pneumatic and electric actuators lies in their power sources. Pneumatic actuators rely on compressed air, which means they require a complex network of components like air compressors, regulators, and filters to function effectively. On the other hand, electric actuators eliminate the need for these bulky components. Instead, they utilize motors, screws, and electronic controls to deliver precise positioning and control.

This shift toward electric actuators offers several benefits, including enhanced precision, better flexibility, and reduced maintenance needs. For packaging machinery designers, the ability to program electric actuators for specific tasks provides unmatched versatility, allowing them to adapt to changing production demands with ease.

---

**Advantages of Electric Actuators Over Pneumatic Ones**

Electric actuators outperform their pneumatic counterparts in terms of precision and control. By integrating advanced motor technologies like servo motors or stepper motors with mechanisms such as ball screws, electric actuators provide unparalleled accuracy in positioning and speed control. This level of control ensures consistent and error-free operations, which is critical in packaging applications where even minor deviations can lead to costly mistakes.

Moreover, electric actuators are far more space-efficient than pneumatic ones. They don’t require large air tanks or extensive piping networks, making them ideal for compact machinery designs. Additionally, electric actuators demand significantly less maintenance, which translates into lower operational costs and higher uptime for manufacturers.

---

**Visualizing the Difference**

To better understand the contrast between pneumatic and electric actuators, let’s compare their respective systems. A typical pneumatic actuator setup includes multiple components such as air compressors, pressure regulators, and control valves. These components not only add complexity but also increase the risk of leaks and malfunctions. In contrast, an electric actuator system consists of just a few essential parts—a motor, driver, and power supply—making it simpler to install and maintain.

Here’s a quick comparison:

| **Component** | **Pneumatic Actuator System** | **Electric Actuator System** |

|--------------------------------|-----------------------------------------------------|-------------------------------------------------------|

| **Main Power Source** | Compressed air | Electric motor |

| **Components Required** | Air compressor, regulator, filter | Driver, programmable controller, power supply |

| **Maintenance Needs** | Frequent checks and repairs | Minimal maintenance |

| **Space Requirements** | High | Low |

---

**Efficiency and Sustainability**

In today’s environmentally conscious world, energy efficiency is a top priority. Electric actuators offer significant advantages in this regard. Unlike pneumatic actuators, which waste energy through air leakage and inefficiencies, electric actuators consume only the energy they need for each task. This not only helps companies meet their sustainability goals but also reduces their operating expenses over time.

Oriental Motor conducted a study in 2022 comparing the energy consumption and carbon emissions of pneumatic and electric actuators under similar operating conditions. The results were striking. Electric actuators consumed far less energy and produced fewer carbon emissions, making them a greener alternative for modern packaging machinery.

---

**Introducing the AlphaStep AZ Series**

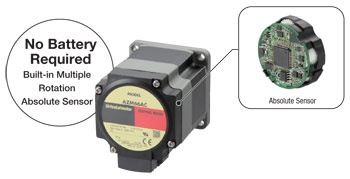

If you’re looking for electric actuators that excel in the packaging and labeling industry, the AlphaStep AZ Series is a standout choice. This product family combines advanced motor technology with user-friendly software, enabling seamless operation and precise control. Whether you’re designing a new packaging line or upgrading an existing one, the AlphaStep AZ Series offers the flexibility and reliability you need to stay ahead of the competition.

For a closer look at the AlphaStep AZ Series, check out the images below:

---

**Conclusion**

While pneumatic actuators have long dominated the packaging industry, electric actuators are proving to be the future. Their superior precision, flexibility, and energy efficiency make them an attractive option for manufacturers seeking to optimize their operations. By embracing electric actuators like those in the AlphaStep AZ Series, packaging machinery designers can build smarter, more sustainable machines that meet the demands of today’s market.

Ready to learn more about how electric actuators can transform your packaging process? Contact us today to explore the possibilities!