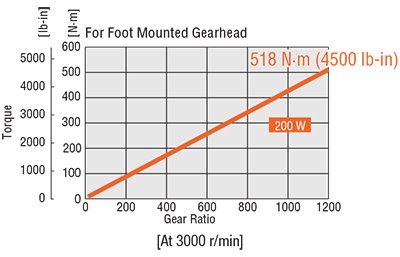

Gearheads are essential components in optimizing motor performance. They come in various types, each offering unique features and characteristics. The gear ratio not only multiplies the motor's torque but also reduces its speed proportionally. By choosing the appropriate gear type and ratio, engineers can finely tune the motor’s performance to match specific application needs.

A motor transforms into a gear motor once a gearhead is attached. The gearhead contains multiple gears that amplify the motor’s torque while simultaneously decreasing its rotational speed based on the gear ratio. The output shaft of the gearhead is where the load connects.

Similar to a belt-and-pulley system, where one pulley rotates slower than another due to differences in diameter, the gearhead’s output shaft spins slower than the motor's pinion shaft by the gear ratio. This setup offers rigidity and allows housing multiple gears in a compact space, unlike belt-and-pulley systems.

This article will explore the different types of gearheads available for brushless gear motors and guide you through the selection process.

**Contents Covered:**

- Introduction to Brushless Motors

- Gear Selection for Brushless Motors

- Motor Sizing Example – Belt Conveyor

- Summary

---

**Introduction to Brushless Motors**

A brushless motor is a type of closed-loop DC motor designed for continuous duty and commutated via a dedicated driver. Known for their compact size, light weight, precise speed regulation, and high efficiency, brushless motors are ideal for variable-speed applications like conveyor belts or automated guided vehicles (AGVs/AMRs). However, they lack holding torque, making them less suitable for positioning tasks.

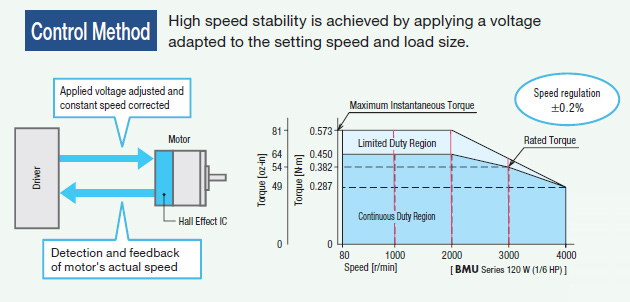

**High-Speed Stability**

Equipped with hall-effect sensors or encoders, the dedicated driver continuously monitors the motor's speed. It adjusts the applied voltage to keep the motor's actual speed close to the desired setpoint. Even under varying loads, the motor's speed fluctuates by no more than ±0.2% (or ±0.05% with encoder-equipped motors).

For applications requiring synchronized speeds, such as pinch belt conveyors, brushless motors provide a more dependable solution compared to open-loop VFD-controlled AC induction motors.

**Space-Saving Design**

Brushless DC motors incorporate permanent magnets in the rotor, resulting in a compact yet powerful design. For instance, a brushless DC motor with the same specifications as an AC induction motor (3.54 inches or 90 mm frame size) is 62% shorter and 62% lighter. This compact structure is beneficial when downsizing machinery or reducing the load on AGVs/AMRs.

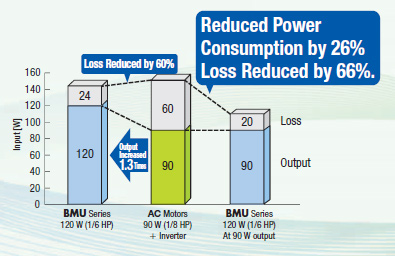

**Energy Efficiency**

Brushless DC (BLDC) motors, featuring permanent magnets in the rotor, experience minimal secondary losses from the rotor. Compared to AC induction motors, BLDC motors can achieve up to 66% less energy loss. For example, at 1/6 HP (90 W), the BMU Series brushless DC motor consumes approximately 26% less power than a VFD-controlled AC motor. Additionally, in the same frame size, a brushless motor can deliver 1.3 times more power than an AC induction motor.

Given the high-speed capabilities of brushless motors (up to 3,000–4,000 RPM), the paired gearheads need to operate quietly at high speeds, offer high permissible torque, and ensure long service life. Our brushless motor gearhead lineup includes parallel shaft gearheads (GFS, JV, JB), parallel shaft gearheads with centered output shafts (CS), hollow shaft right-angle gearheads (JH), and hollow shaft flat gearheads (FR).

**Benefits of Adding a Gearhead**

Attaching a gearhead to a motor provides several advantages:

- **Increased Torque**: Multiplies the motor's torque.

- **Reduced Speed**: Decreases the motor's rotational speed.

- **Stabilized Speed Fluctuations**: Minimizes variations in speed.

- **Vibration Reduction**: Reduces mechanical vibrations.

- **Overrun Reduction**: Limits excessive speed after stopping.

- **Increased Load Capacity**: Supports higher axial and radial loads.

When selecting gearheads, always consider the rotation direction of the gearhead shaft, as some gearheads reverse the shaft rotation depending on the gear ratio.

**Choosing the Right Gearhead**

Our brushless gear motor lineup is divided into two categories: long-life and high-torque options. These gearheads are designed to complement the high-performance characteristics of brushless motors, ensuring longevity and reliability.

In conclusion, selecting the right gearhead is crucial for maximizing motor efficiency and meeting application-specific requirements. Understanding the benefits and limitations of different gearheads enables engineers to optimize motor performance effectively.

---

Let me know if you'd like further clarification or additional details!