Warehouse Fire Safety Tips

Box Guideway Machining Centers

Box guideway machining center also call hard rail machining center in China, it refers to a casting part where the guide rail and the bed are integrated, and then the guide rail is processed on the basis of the casting, which is a type of hard guide rail. The shape of the guide rail is cast on the bed, and then processed into a guide rail through quenching and grinding. The hard rail used in the hard rail machining center is generally a rectangular structure, commonly known as a rectangular guide rail or box guide rail. The Box way machining center machining center adopts sliding friction, which leads to a larger contact surface and high rigidity and strength. Therefore, the box guideway machining center is more suitable for heavy-duty cutting and is suitable for heavy-duty mold processing.

Advantages of box guideway Machining Centers: Box Guideway Machining Center,Small Cnc Machining Center,Cnc Machining Center Vertical,Cnc Vertical Machining Center Dongguan Liyang Intelligent Technology Co., Ltd , https://www.leyomachine.comTips for Warehouse Fire Safety

With the growing frequency of fire incidents, ensuring warehouse fire safety has become more critical than ever. Fires in warehouses can be caused by a variety of factors, including electrical malfunctions, faulty equipment, and human error. To minimize these risks, it's essential for warehouse owners and managers to implement proactive fire prevention strategies. By focusing on regular maintenance, employee training, and the use of advanced fire detection systems, businesses can significantly reduce the likelihood of a fire occurring.

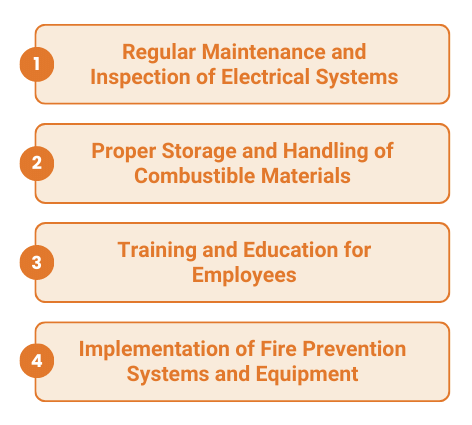

Four Essential Tips for Effective Fire Prevention

Preventing fires requires a comprehensive approach that includes routine checks, staff education, and the installation of fire protection systems. Here are four key tips to help you safeguard your warehouse:

1. Regular Maintenance of Electrical Systems

Electrical issues are one of the leading causes of warehouse fires. To prevent this, schedule regular inspections of all electrical systems, including wiring, panels, and machinery. This helps identify potential hazards before they lead to a fire.

2. Safe Storage of Flammable Materials

Many materials found in warehouses, such as cardboard, wood, and paper, are highly flammable. Store these items away from heat sources and ensure they are stacked properly to avoid tipping or collapse. Keeping flammable materials organized and separated is an essential step in fire prevention.

3. Employee Fire Safety Training

Your employees are your first line of defense against fire. Provide them with proper training on handling flammable materials, using fire extinguishers, and recognizing early signs of a fire. Regular drills and refresher courses can make a big difference in emergency preparedness.

4. Installation of Fire Detection and Suppression Systems

Investing in fire detection systems like smoke detectors, sprinklers, and heat sensors can provide early warning and help contain fires before they spread. These systems are vital for protecting both people and property.

Preparing for Emergencies: The Importance of an Emergency Response Plan

An emergency response plan is a crucial part of any warehouse safety strategy. It ensures that everyone knows what to do in case of a fire, reducing panic and improving coordination. A well-designed plan should include clear evacuation routes, designated assembly points, and roles for each employee.

It’s also important to communicate effectively during an emergency. Using public address systems, digital alerts, or other communication tools can keep everyone informed. Regularly testing and updating the plan ensures it remains effective and relevant.

Protect Your Warehouse with MoviTHERM’s Advanced Fire Detection Solutions

Preventing warehouse fires is not just about reacting to emergencies — it’s about being proactive. MoviTHERM offers innovative thermal imaging solutions that detect early signs of fire, even in areas where traditional smoke detectors may fail. Their systems monitor temperature changes and alert managers to potential overheating or abnormal conditions, giving them time to act before a fire starts.

In addition to early fire detection, MoviTHERM provides condition monitoring tools that help prevent equipment failures. By tracking the health of your machinery, you can identify and resolve issues before they escalate into dangerous situations.

With MoviTHERM’s technology, warehouse managers can take control of their fire safety strategy, protect their teams, and safeguard valuable assets. Investing in early detection and smart monitoring is a powerful way to enhance overall warehouse safety.

Learn more about how MoviTHERM’s solutions can help you create a safer working environment.

1. Able to withstand larger loads, suitable for rough machining machines with large cutting amounts and large feed rates.

2. Due to the large contact area of the guide rail, the machine tool operates more smoothly, making it suitable for factories with high requirements for machine tool vibration.

Disadvantages of box guideway machining centers:

1. Shorter service life. Under the same maintenance and usage conditions, the service life of box guideways is generally shorter than linear guide machining center, because box guideways operate with sliding friction, while linear guide operate with rolling friction, resulting in greater wear and tear.

2. The repair cost is too high. The maintenance of box guideway machining center is much more difficult and costly than linear guideway machining center. If there is insufficient scraping allowance, it may involve disassembling all the large parts of the machine tool, performing quenching and mechanical processing again, and even more importantly, recasting the large parts. The wire gauge only needs to replace the corresponding linear guide, which will not greatly affect the use of related large parts.

3. The running speed of machine is low, and box guideways machining center usually cannot withstand too fast running speed due to their movement mode and the excessive friction they bear, which contradicts the current machining concept to a certain extent. Especially many factory workers do not have the corresponding maintenance knowledge for machine tools. Many times, they only know how to use the machine tool, but largely neglect the maintenance of the machine tool. The maintenance of the machine tool track is of utmost importance. Once the lubrication of the track is insufficient, it can cause the track to burn or wear excessively, which is fatal to the accuracy of the machine tool.