A U-tube heat exchanger is a type of shell and tube heat exchanger commonly used in industries like chemical and petrochemical sectors. It is particularly known for its ability to manage thermal expansion, making it ideal for applications with significant temperature differences between the two fluids.

The key component of this design is the U-tube bundle, which allows for flexibility and prevents pressure build-up on the tubes. This feature makes it highly suitable for high-temperature environments where other types might struggle.

Table of contents

- U Tube Heat Exchanger Specification

- U Type Heat Exchanger Function

- U Tube Bundle Heat Exchanger Features

- U Tube Heat Exchanger Design

- U Tube Type Heat Exchanger Diagram

- U Tube VS Straight Tube Heat Exchanger

- Difference Between Floating Head and U Tube Heat Exchanger

- U Tube Condenser Applications

- U Tube Shell and Tube Benefits

- U Tube Exchanger Advantages

- Disadvantages of U-Tube Heat Exchanger

- U Tube Heat Exchanger Calculation

- Cross Over Temperature of U Tube Shell and Tube

U Tube Heat Exchanger Specification

| U Tube Heat Exchanger Size |

- 0.010 to 1.500 inch OD

- 0.254 to 38.1 mm OD

|

| Manufacturing Type |

- Seamless

- Welded

- ERW

- Fabricated

|

| Major parts |

- Front Header

- Rear Header

- Tube bundle

- Shell

|

| Dimensions Standard |

- ASME B16.9

- MSS-SP-43

- ASME B16.28

|

| Manufacturing Method |

- Hot Finished

- Cold Finished

|

| Material |

- Stainless Steel

- Duplex & Super Duplex Steel

- Carbon Steel

- Alloy Steel

- Nickel Alloy

|

| Certificates |

- MTC EN 10204 3.1/3.2

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- NACE MR0175

- NACE TM-0284

- NACE MR0103

- ISO 15156

|

| Origin |

- Japanese

- Korean

- Indian

- Russian

- Ukraine

- USA

- European

|

| Application |

- High-temperature

- Low-temperature

- Very high pressure

|

| Srface Treatments |

- Precleaned

- Cleaned

- Passivated

- Pickled

|

| Short Radius Elbow Standard |

|

| Finish |

- 180 grit polished

- Matt finish

- 320 grit

- Mirror

- Solution annealed

- Annealed & Pickled

- No.4

- 2B

- Cold Drawn

- BA polishing

- 400 grit

- Bright Annealed

- 600 grit

|

| Value Added Services |

- Cutting

- Polishing

- Threading

- Beveling

|

Discover the features and functions of U-tube condensers

U Type Heat Exchanger Function

A U-tube heat exchanger works by allowing one fluid to flow through the tubes while the other flows around them. This design is especially effective in high-temperature and high-pressure environments.

U Tube Bundle Heat Exchanger Features

- Excellent heat transfer efficiency

- Fixed at both ends for unidirectional flow

- Easy to maintain and clean

- Can handle high pressure and temperature

U-tube bundle heat exchangers provide efficient heat transfer with a compact design

These units are designed to maximize heat transfer while minimizing energy consumption and operational costs. They offer strong pressure resistance and excellent thermal performance, leading to improved overall efficiency.

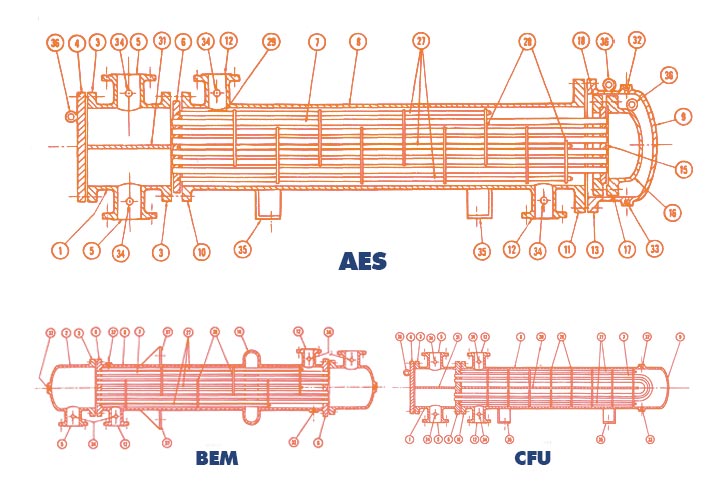

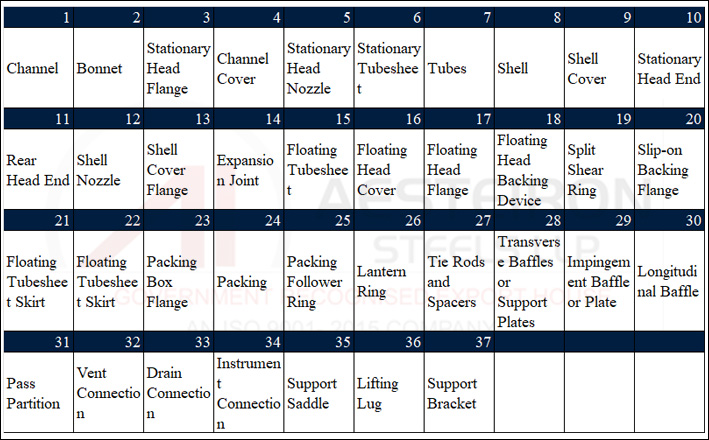

U Tube Heat Exchanger Design

Understand the components and working principle of a U-tube shell and tube heat exchanger

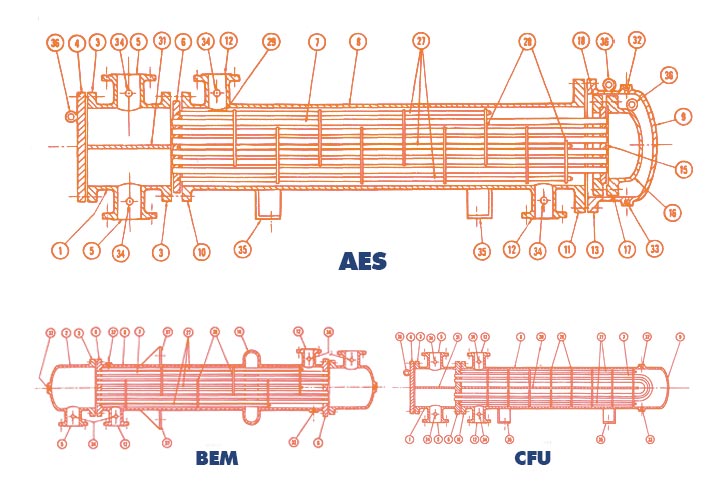

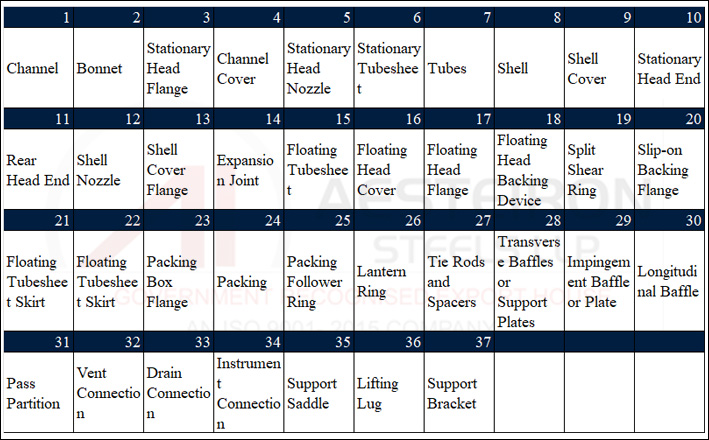

The U-tube shell and tube heat exchanger operates using a shell and tube configuration to facilitate heat exchange. It consists of a shell and multiple tubes. The following image provides more details about its structure and components.

U tube type heat exchanger Diagram

U Tube VS Straight Tube Heat Exchanger

| Feature |

U-Tube |

Straight |

| Construction |

Compact and robust |

Simpler |

| Design |

Fixed at both ends |

Bundled in a shell |

| Cost |

High |

Low |

| Thermal Expansion |

More |

Less |

| Heat Transfer Area |

Good |

Better |

| Maintenance |

More |

Easier to maintain |

| Space Requirements |

Compact |

Bulkier |

| Lifespan |

Longer |

Varies with design |

Difference Between Floating Head and U Tube Heat Exchanger

| Feature |

Floating Head Heat Exchanger |

U-Tube Heat Exchanger |

| Design |

One end is fixed and the other is floating |

Fixed at both ends |

| Maintenance |

Easier |

More challenging |

| Heat Transfer Area |

Larger |

Efficient |

| Space Requirements |

Bulkier |

Compact |

| Cost |

High |

Low |

| Lifespan |

Long |

Robust |

U-type heat exchangers are widely used in petroleum and chemical machinery

Heat exchangers are essential for transferring heat between two separate channels, either directly or via a barrier. In the petroleum and chemical industries, U-type heat exchangers are preferred due to their compact design, high heat productivity, and ability to withstand high pressure. This ensures reduced risk of failure and enhanced safety under harsh conditions.

U Tube Condenser Applications

- Pressure Vessels

- High Pressure Equipments

- Cryogenic Pressure Vessels

- Boilers

- Air Cooler Tubes

- Tube Sheets of Heat Exchangers

- Refineries

- Air Pre Heater

- Fertilizer Plants

- Chemical Factories

- HVAC Systems

U Tube Shell and Tube Benefits

- High Efficiency

- Enhanced Heat Transfer

- Compact Design

- Less Maintenance

- Versatility

- Excellent Durability

- Cost Effectiveness

- Easy to Install

Explore the advantages and disadvantages of U-tube heat exchangers

U Tube Exchanger Advantages

- Recycled

- Energy-saving

- Wide range of designs

- Cost-effective

- Various material options

- Space-saving designs

- Good thermal compensation

- Easy maintenance

- Handles various flow rates, fluids, and temperatures

Disadvantages of U-Tube Heat Exchanger

- Limited for large temperature variations

- May warp due to temperature differences

- Requires more space

- Needs regular cleaning

- Complex structure

- Prone to internal leakage

U Tube Heat Exchanger Calculation

Cross Over Temperature of U Tube Shell and Tube

| Temperature |

Water |

Oil |

| Outlet |

51.5 |

50 |

| Inlet |

30 |

80 |

| Flow Rate |

15 L/min |

25 L/min |

38CrMoALA+PTA Screw

38Crmoala+Pta Screw,Nitrided Steel Screw,Nitriding Barrel,Single Screw Extruder

ZHEJIANG HUAYE PLASTICS MACHINERY CO.,LTD , https://www.hayeur-group.com