Testing The Elios 3 Surveying Payload at ICL Boulby Mine

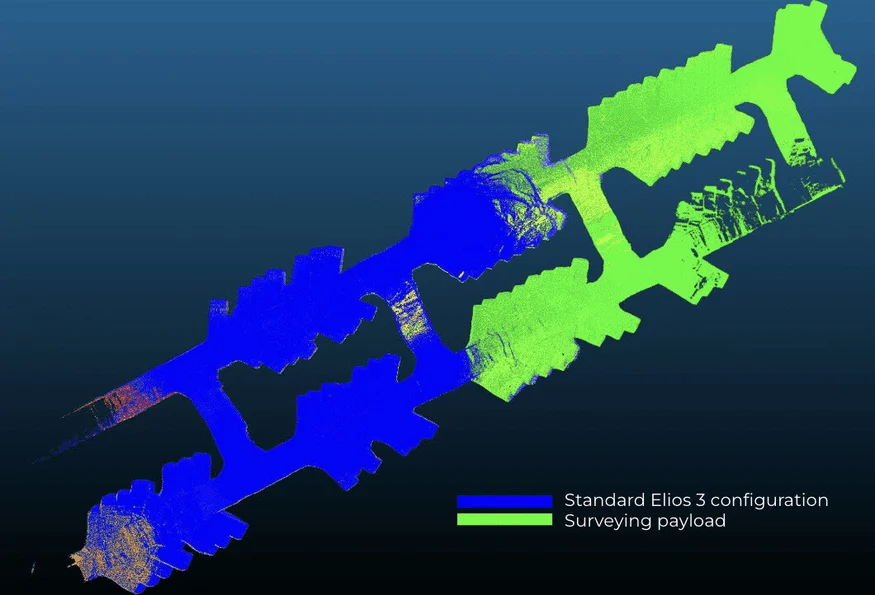

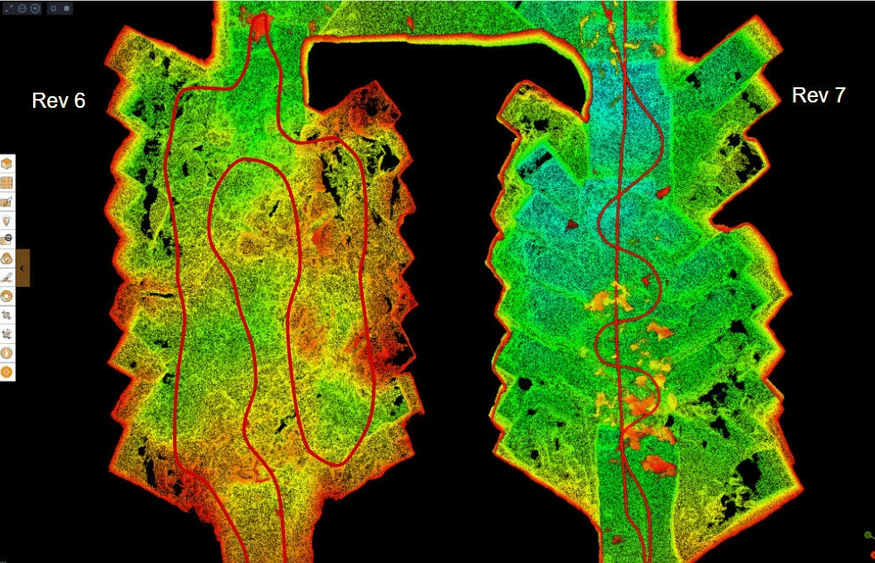

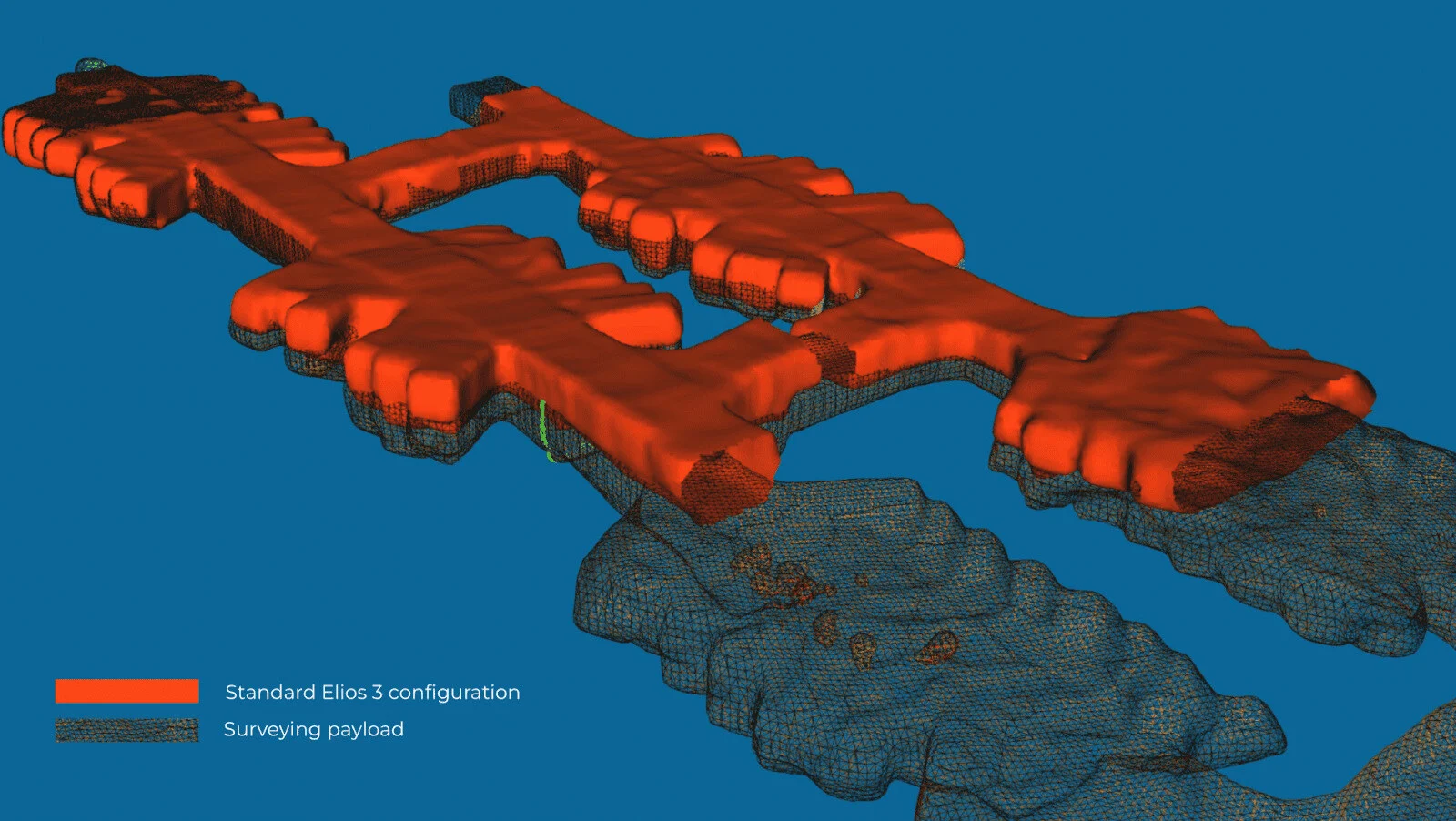

Discover how the new Surveying Payload made surveying faster and more efficient in the challenging environment of ICL Boulby Mine. Enhanced Data Coverage The Elios 3’s new LiDAR payload offers an extended range, allowing it to cover larger areas in the same amount of time with improved precision. This is a game-changer for underground environments where space is limited and accuracy is crucial. Increased Speed With the Surveying Payload, data collection is significantly faster. At ICL Boulby, a 340-meter tunnel was surveyed in just 10 minutes, cutting flight time by half compared to previous configurations. Simplified Flight Planning The Rev 7 LiDAR allows for easier and more efficient flight planning due to its improved range and coverage. This led to a 50% reduction in flight time at ICL Boulby, making surveys more manageable and less complex. Improved Accuracy The new payload reduces LiDAR drift by up to five times compared to the standard configuration, delivering greater reliability even in difficult conditions. This level of precision is vital for accurate mine mapping and safety compliance. When Flyability tested the new Surveying Payload for the Elios 3, they chose ICL Boulby as the ideal location. The mine already uses the Elios 3’s LiDAR data for regular inspections, so comparing the new Ouster Rev 7 LiDAR with the original setup provided valuable insights into performance improvements. ICL Boulby is the only polyhalite mine globally, located north of Whitby in Northeast England. Originally established in 1968 for potash mining, it has since transitioned to extracting polyhalite, a key organic fertilizer. The mine stretches over 1,200 meters deep and extends beneath the North Sea, reaching up to 12 kilometers offshore. One of the main challenges at ICL Boulby is the vast network of old and active workings that need careful mapping. These historical structures must be documented accurately to prevent hazards like gas or water inrushes. Accurate records are not only essential for safety but also required by UK regulations. Simon Pollitt from ICL Boulby proposed using the Elios 3 for mapping these mine workings. The drone enables safe and efficient surveys in areas that would otherwise be inaccessible, supporting the mine’s advance and retreat mining method. After nine months of use, the Elios 3 has become a critical tool for their surveying and volumetric projects. A 340-meter tunnel once required four flights with the original Elios 3 setup, taking 20 minutes total. Now, with the new Surveying Payload, the same area can be covered in just one flight, cutting time in half and preserving battery life. Double the coverage: Overlay showing the difference in coverage between the two LiDAR configurations. The new Ouster LiDAR OS0-128 Rev 7 offers enhanced accuracy, better robustness, and a longer range. It captures denser point clouds in less time, which can be automatically processed using FARO Connect software. This makes data preparation faster and more reliable. Thanks to the increased range, post-processing time is cut in half, as there's no need to merge multiple scans. This efficiency is a major benefit for teams working in tight deadlines and complex environments. Simplified flight path for comparable results: The left image shows the original survey payload's trajectory, while the right demonstrates the new Surveying Payload. LiDAR drift is a common issue, especially in the vertical (Z) axis. With the new Surveying Payload, Simon noticed a significant improvement in reducing this drift. The enhanced accuracy now aligns closely with terrestrial laser scanners used by ICL Boulby, streamlining post-processing and enabling more precise planning for tasks like water drainage. Almost 5x more accurate on the Z-axis: The red scan shows drift from the old payload, while the black scan reflects the improved accuracy of the Rev 7 LiDAR. This level of precision opens up new possibilities for ICL Boulby, including more detailed mapping and safer, more efficient operations. Currently, ICL Boulby uses the Elios 3 for mapping mine workings and measuring stockpile volumes. However, previous limitations with drone size and maneuverability restricted their ability to survey large indoor areas effectively. With the new Surveying Payload, they’re now looking to expand their capabilities further. "The Elios 3 Surveying Payload is a game changer for our operations. The faster data collection and higher accuracy alone make it worth switching from the standard sensor to the new one, and we're excited about the new projects it will enable," - Simon Pollitt, Chief Surveyor at ICL Boulby The improved Z-axis accuracy and reduced flight times mean fewer missions are needed for large-scale surveys, helping the team cover more sites efficiently while maintaining high standards of accuracy. Overall, the new payload is a smart upgrade that saves time, reduces costs, and ensures safer inspections for the entire team. For more information on the Elios 3 Surveying Payload and how it could benefit your surveying needs, reach out to us. Our team of experts is here to help you every step of the way, whether you're just starting with drones or looking to enhance your current setup. The most accurate surveys with the Elios 3 are completed with the Surveying Payload, offering unmatched performance in challenging environments. Injector Pressure Regulator Valve Injector Pressure Regulator Valve,F81Z9C968AA,1841086C91 Wenzhou Zhongking Parts Co.,ltd , https://www.oemvvt.comTesting the Elios 3 Surveying Payload at ICL Boulby Mine

Key Advantages of the Elios 3 Surveying Payload

Exploring the World's Only Polyhalite Mine – ICL Boulby

Reducing Drone Flight Time by Half with the New Surveying Payload

VIDEO: Fly-through of the data captured in one flight by the Elios 3 Surveying Payload

Improving Z-Axis Accuracy for Better Alignment with Terrestrial Scans

Expanding Use Cases with the New Surveying Payload