British Type Anm Cutting Nozzle

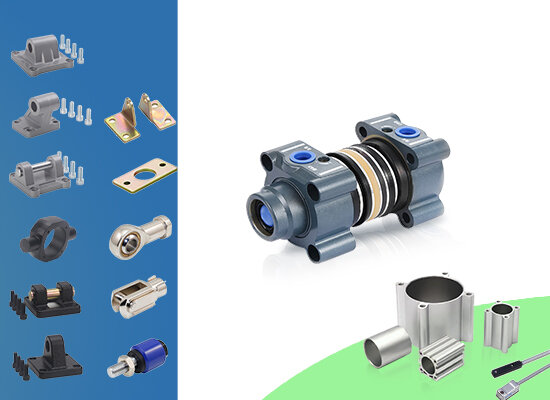

Pneumatic Cylinder Accessories Air cylinder accessories of different models and different standards are generally not interchanged. When ordering Pneumatic Cylinder accessories, please note the specifications and parameters of the corresponding cylinder. If the standard and model of the cylinder are same, the cylinder accessories can be used interchangeably.Pneumatic Cylinder Tube. Pneumatic cylinder is the executing component in pneumatic systems, mainly used to convert the pressure energy of compressed air into mechanical energy, generating linear or oscillatory motion. The construction of pneumatic cylinders is complex and includes multiple key components. Below are some common components and their functions: Cylinder Barrel: This is the main body of a cylinder, typically a cylindrical container used to accommodate pistons and other internal components. The cylinder barrel must be strong enough to withstand the pressure of compressed air inside. Piston: located inside the cylinder and in close contact with the inner wall of the cylinder barrel. When compressed air enters the cylinder, the piston moves inside the cylinder barrel, generating thrust or tension. Piston Rod: The part that connects the piston to the external mechanical structure and is used to transmit the linear motion of the piston. End caps/caps: fixed at both ends of the cylinder barrel, sealing the internal space of the cylinder and supporting the piston rod and other components. The front cover usually includes a guiding component for the piston rod. Seals: Used to prevent gas leakage and ensure smooth movement of the piston within the cylinder barrel. It mainly includes piston sealing rings, rod sealing rings, and dust sealing rings. Guide bushing: Helps the piston rod maintain the correct direction of movement, reducing friction and wear. Buffer Device: Some cylinders are equipped with buffer devices to slow down the speed of piston movement when it reaches the end point, preventing impact and noise. Magnetic switches: Some cylinders have built-in or external magnetic switches used to detect the position of the piston and control the action of the cylinder. Exhaust Flow Control Valve: Sometimes integrated into the cylinder, it is used to regulate the exhaust speed and control the speed of the piston. These components work together to enable the pneumatic cylinder to effectively convert the energy of compressed air into the required mechanical motion. According to specific application requirements, pneumatic cylinders may also include other specially designed components to meet specific functional requirements. Pneumatic Cylinder Accessories,Pneumatic Cylinder Parts Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

British Type ANM Cutting Nozzle

Item

British Cutting Nozzle

Model Size

ANM Thickness Orifice

1/32

3-6Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 0.8

3/64

5-12Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 1.2

1/16

10-75Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 1.6

5/64

70-100Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 2.0

3/32

90-150Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 2.4

1/8

190-300Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 3.2

Changzhou Huarui Welding & Cutting Co., LTD

Since 1985, Changzhou Huarui has grown into one of the largest manufacturers of welding and cutting equipment and accessories in China. We use advanced manufacturing technology and specialized techniques to deliver high-quality products.

Our company specializes in producing MIG, TIG, and Plasma torches along with their spare parts. With various connectors such as Euro, Lincoln, Miller, and Tweco, we can ensure compatibility with a wide range of foreign equipment.

1. MIG Welding Torches

Binzel, Bernard, Tweco, Esab, Lincoln/Tregaskiss, Panasonic/OTC, MAXI, Kemppi, Fronius, Mechafin.

2. TIG Welding Torches

WP-24, WP-9, WP-17, WP-26, WP-20, WP-18, etc.

3. Plasma Cutting Torches

Trafimet, Cebora, Panasonic/Esab

FAQ

Q1: Can I get samples to check the quality?

A: Yes, we can provide samples. For standard products, the sample cost varies depending on the quantity you request. For new items, there may be a minimum order quantity for samples.

Q2: Can I have my logo printed on the packaging?

A: Yes, we can customize the packaging according to your requirements. Please send us your trademark authorization letter before production.

Q3: How do you ensure product quality?

A: Every Huarui torch undergoes rigorous testing before packaging, including insulation resistance tests, high voltage tests, air/water flow tests, and air/water seal tests. If any defective items are found, we will either credit your account or replace them in the next shipment.

Q4: What is the order process?

A: First, we discuss the details via email or TM. Then we issue a Proforma Invoice (PI) for your confirmation or a Trade Assurance Order payment link. You need to make a full prepayment before we start production. Once the payment is received, we begin processing the order. It usually takes 5–15 days if the item is not in stock.