400kw Supersonic Induction Heater IGBT Control with Air Condition

Miniature Ball Screws,Lead Screw Backdrive,Back Drive Ball Screw,Miniature Ball Screw Assembly Suzhou Industrial Park Hojama Technology Co., Ltd , https://www.hojama-tech.com

Applications of the Induction Heater:

A. Heating (Hot Forging, Hot Fitting, and Smelting):

1. **Hot Forging** involves shaping metal parts at high temperatures using presses or forging machines. It is widely used for manufacturing components like watch cases, handles, molds, kitchenware, and more.

2. **Hot Fitting** refers to joining different materials by heating them based on thermal expansion. Examples include welding copper cores to aluminum sheets in radiators, sealing plastic tubes, and attaching motor rotors.

3. **Smelting** is the process of melting metals into liquid form, commonly used for iron, steel, copper, aluminum, and other precious metals.

B. Heat Treatment (Surface Quenching):

This process enhances the hardness and durability of metal parts. Common applications include quenching tools like pliers, wrenches, hammers, and automotive components such as crankshafts, valves, and gears.

C. Welding (Brazing, Silver Soldering, and Soldering):

Used to join similar or dissimilar metals by melting solder at a specific temperature. Applications include cutting tools, hardware products, electric kettle bases, and various mechanical components.

D. Annealing (Tempering and Normalizing):

Annealing improves the structure and properties of metals. It is often applied to stainless steel products, kitchenware, and other metal parts to enhance their flexibility and strength.

Key Specifications:

Model

GYS-400AB (Three Phase)

Input Voltage

340V - 430V

Input Current

600A

Frequency Range

10-50kHz

Output Current

400-10500A

Cooling Water Flow Rate

0.08-0.16MPa, 25L/min

Water Temperature Protection

80°C

Product Dimensions

Main Unit: 1500x1100x1150 mm

Transformer: 1300x600x820 mm

Net Weight

Main Unit: 450 kg

Transformer: 300 kg

Delivery Time: Within 25 working days.

Shipping Options: By Sea, Air, or Express.

Optional Accessories Available:

1. Chiller

2. Custom Coil Design

3. Infrared Thermometer

4. Backup Electronic Boards

5. Forging/Melting Furnace, Hardening Fixtures

Factory View

Application Photos

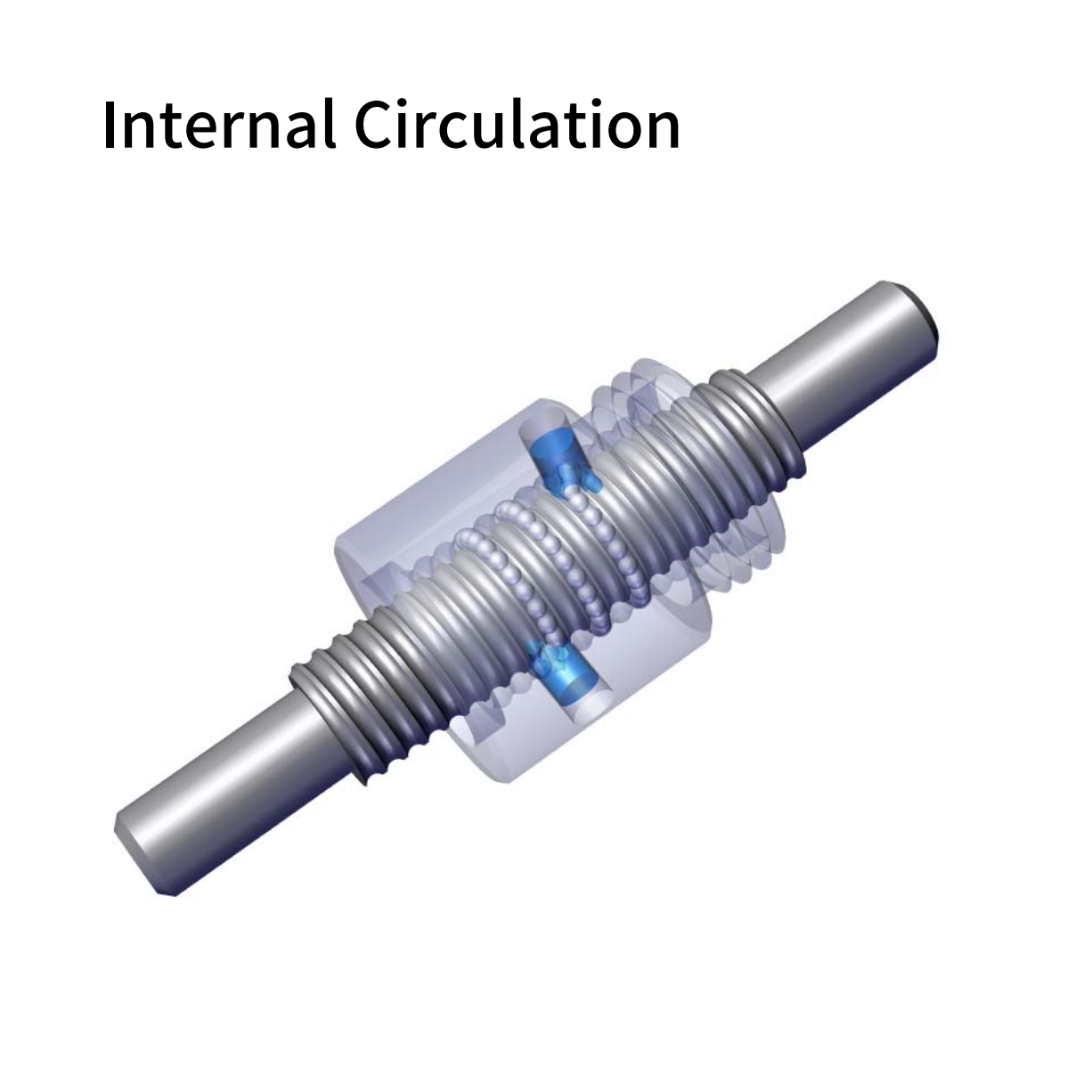

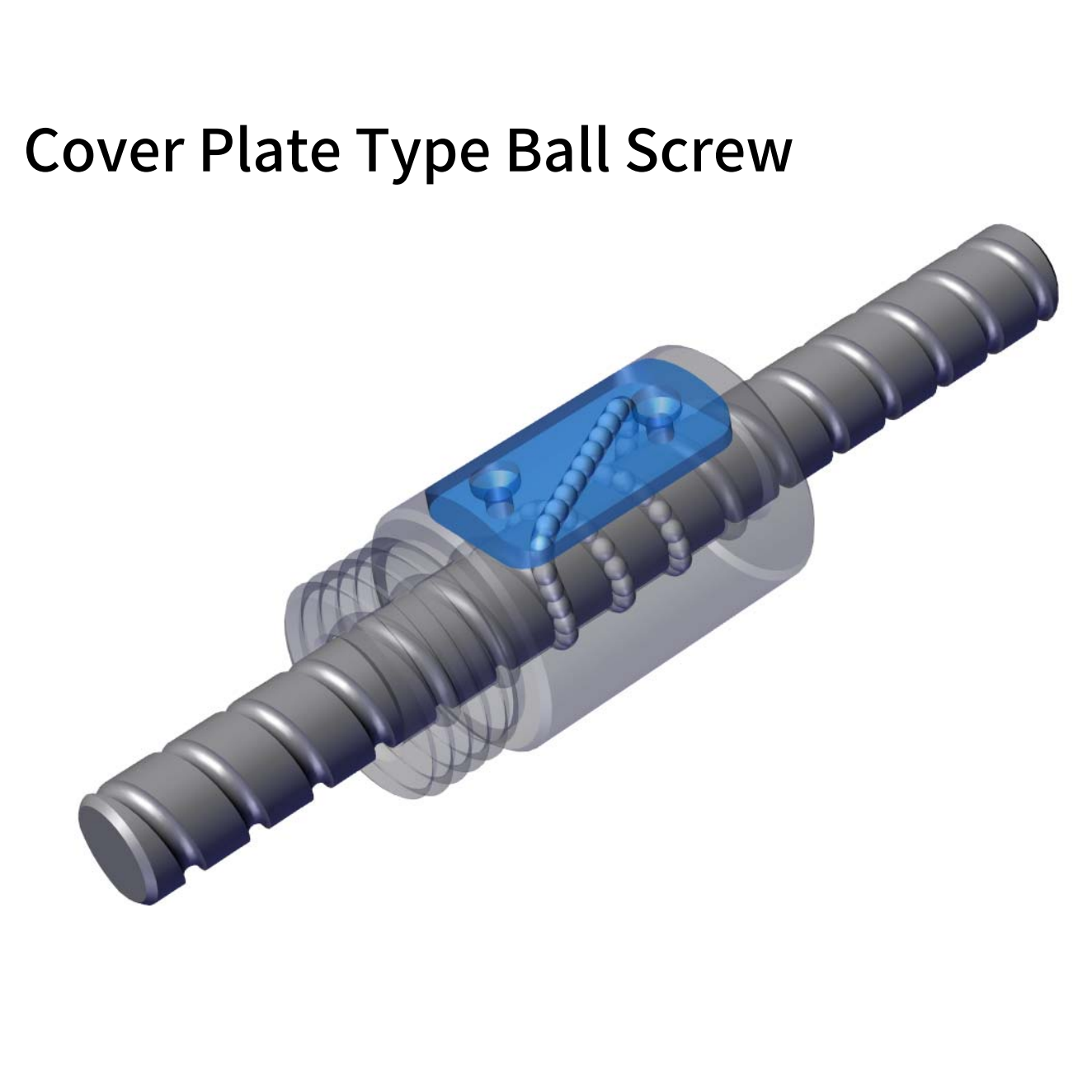

Miniature ball screws--Hojama precision ground ball screws

Anti-rust treatment for ball screws:

I. Surface pretreatment of the objects to be rust-proofed

II. Application of anti-rust oil